DefExpo 2022 is the 12th edition of India’s Flagship Defence Exhibition on Land, Naval & Homeland Security Systems, organised by Defence Exhibition Organization (DEO), Government of India, Ministry of Defence, Department of Defence Production. It will be held this year in Gandhinagar, Gujarat.

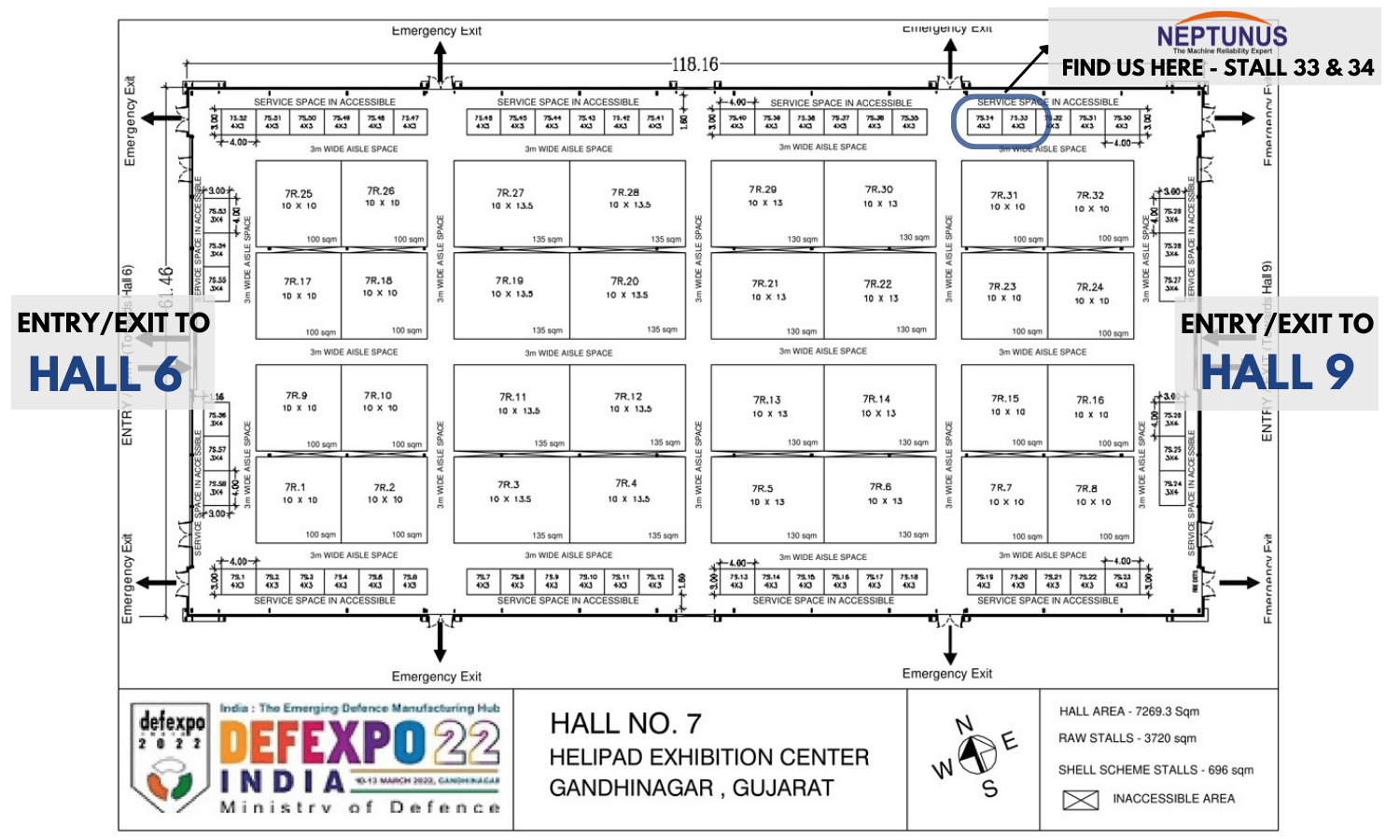

The main DefExpo exhibition will be held at Helipad Exhibition Centre (HEC) and the inaugural or official function & seminars will be held at Mahatma Mandir Convention and Exhibition Centre (MMCEC).

The defence exhibition will be spread across an area of 76,000 square metres with over 1028 exhibitors participating from 70 countries, with an expected total of 3000+ delegates and 12 lakh visitors.

It’s a world-renowned platform for the Armed Forces, DPSUs and industries to showcase their equipment and skill sets that hold the potential to be an addition to the Indian Defence Ecosystem.

Neptunus is one of the true machine reliability experts with 25+ years of delivering reliable engineering solutions, completing 2000+ assignments across various industry segments with customers in more than 25 countries. Our vision is to leverage real-time machine health data to eliminate the pain of unplanned shutdowns at the earliest possible time. We are also the sole authorised sales and service representatives for some of the renowned engine brands like Niigata & EMD.

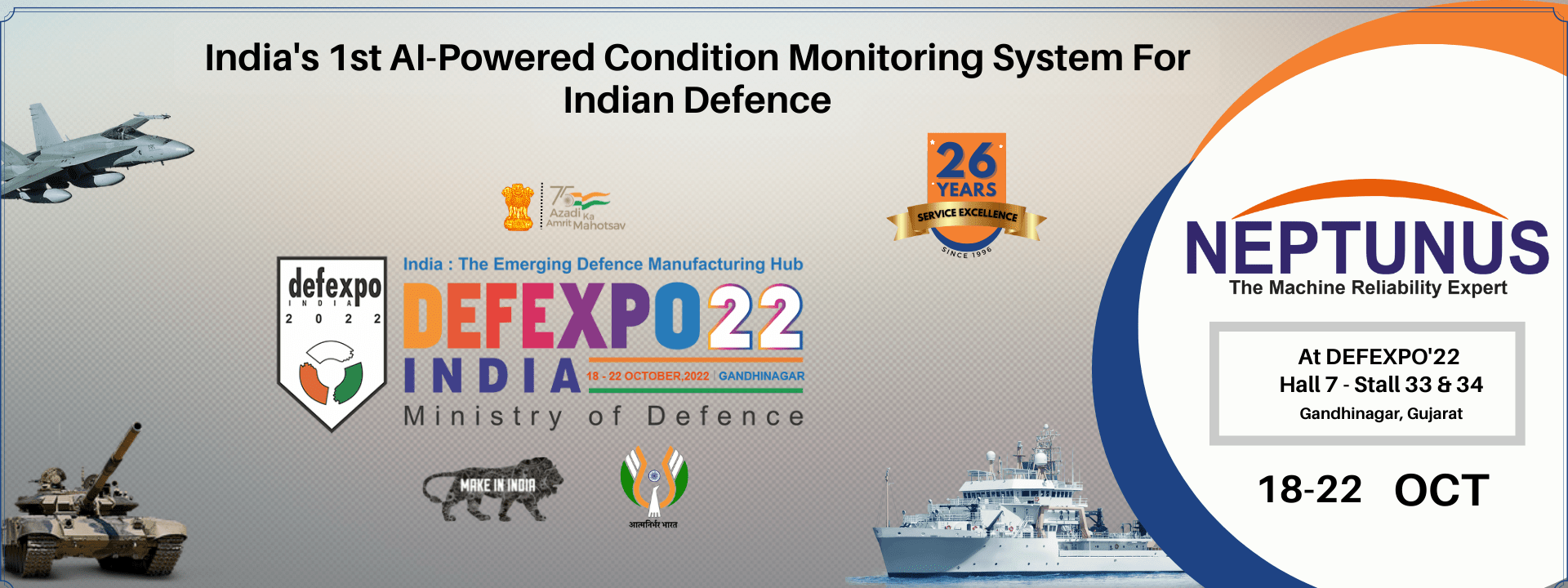

We are going to be participating for the first time in a Defence Exhibition at this year’s DefExpo 2022 Gandhinagar, Gujarat.

At this year’s Defence Exhibition at Gandhinagar, Neptunus will be showcasing its AI-powered preemptive condition monitoring tool that has been successfully validated on all types of engines and test benches in the following:

For the Indian Army on BMPT-70 & T-90 across several army sites.

Validated and trialed for the first time on the engines of Indian Navy warships and submarines.

Surface and off-shore patrol units.

On Tata 697 and 6BT overhauled engines, as well as an Ashok Leyland 6ET used engine.

On Overhauled Greaves Cotton TBDv8 Engine, Used Greaves Cotton TBDv8 & PES-100 Engine.

Safely extend overhauls, eliminate unplanned breakdowns of your engine with continuous course correction.

Easily mounted inside the BMP Cabin along with the display unit.

Withstood operating conditions without failure.

There was no impact of ambient vibrations on the technology readings.

Reading was in sync with test bench results.

Flotation test was passed with flying colours.

Predicts faults at a nascent stage.

● Extend mean time between overhauls of Engine.

● Pin Points Fault at particular engine Serial Numbers.

● Save operating & maintenance Costs.

● Test engine in situ before sending them to ABWs.

● Pre-empt engine failures by predicting residual life.

● Remote Monitoring via Secure IOT Platforms.

● Real-time condition of engines in Tanks is crucial at times of mechanised warfare.

One of its kind, Torsional Vibration based engine condition monitoring system that helps identify faults in rotating equipment eg. Engines, gearbox, motor, bearings, turbines etc. months before any of the conventional vibration based monitoring systems that too at a component level. It measures and analyses angular vibrations at the source, i.e., the main shaft, where the earliest manifestation of emerging faults can be detected.

Oil Quality Management System – Neptunus believes in adopting a more holistic approach towards effective management of oil which comprises of both

We aim to eliminate intuitively decided periodic oil replacements made without any qualitative data.

● Oil-Quality is determined by taking into account over 20 parameters of oil degration.

● Filtration system removes sources of oxidation and keeps the oil continuously clean.

● Follow the optimal oil replacement period.

● Get detailed Oil-Quality data based on several key oil quality indicators.

● A Mobile app that will display key parameters of your oil health.

● Download an oil health log and graph trends over time.

1. Employs bypass loop (kidney loop) to improve efficiency of filtration.

2. It is a highly efficient filtration system (β3 >929), capable of removing water, solid particles, resins, oxidation sludge, varnish, and other organic contaminants from the oil.

3. Oil flow is axial, not radial like in the case of other filters.

4. Uses a patented depth filtration technology to capture the maximum number of contaminants.

5. Bypass filtration system enhances efficiency, as it operates on ideal conditions such as:

● Reduced flow.

● Minimal pressure.

● No stress by flow and pressure pulsations.

1. The Oil Quality Monitoring Sensor generates an electric field within the oil.

2. The ratio of capacitance and conductance of oil is calculated by the sensor.

3. This ratio is compared with the Tan Delta oil database and a TDN (Tan Delta Number) is generated.

4. TDN is a measure of oil quality. It ranges from 0 to 1200.

One of its kind, Torsional Vibration based engine condition monitoring system that helps identify faults in rotating equipment eg. Engines, gearbox, motor, bearings, turbines etc. months before any of the conventional vibration based monitoring systems that too at a component level. It measures & analyses angular vibrations at the source i.e. main shaft, where earliest manifestation of emerging faults can be detected.

Oil Quality Management System – Neptunus believes in adopting a more holistic approach towards effective management of oil which comprises of both

We aim to eliminate intuitively decided periodic oil replacement made without any qualitative data.

● Oil Quality is determined by taking into account over 20 parameters of oil degrations.

● Filtration System Removes Sources of Oxidation & Keep the Oil Continuously Clean.

● Follow Optimal Oil Replacement period.

● Get Detailed Oil Quality Data based on several key oil quality indicators.

● Mobile app that will display key parameters of your Oil Health.

● Option to download Oil health log and plot trends over time.

At DefExpo 2022 Exhibition, you could find us at stall 33 & 34 at Hall 7 in the helipad exhibition centres.

Neptunus Power Plant Services Pvt. Ltd.

India

Neptunus Main Office

A 554/555, TTC Industrial Area,

MIDC Mahape, Navi Mumbai,

Maharashtra 400710, India.

UAE

Neptunus Global Trading (NGT)

Ras Al Khaimah Economic Zone,

RAKEZ Al Mamourah Street,

Ras Al-Khaimah, UAE.

France

dataVIB Impédance

80 Dom. de Montvoisin,

91400 Gometz-la-Ville,

France.