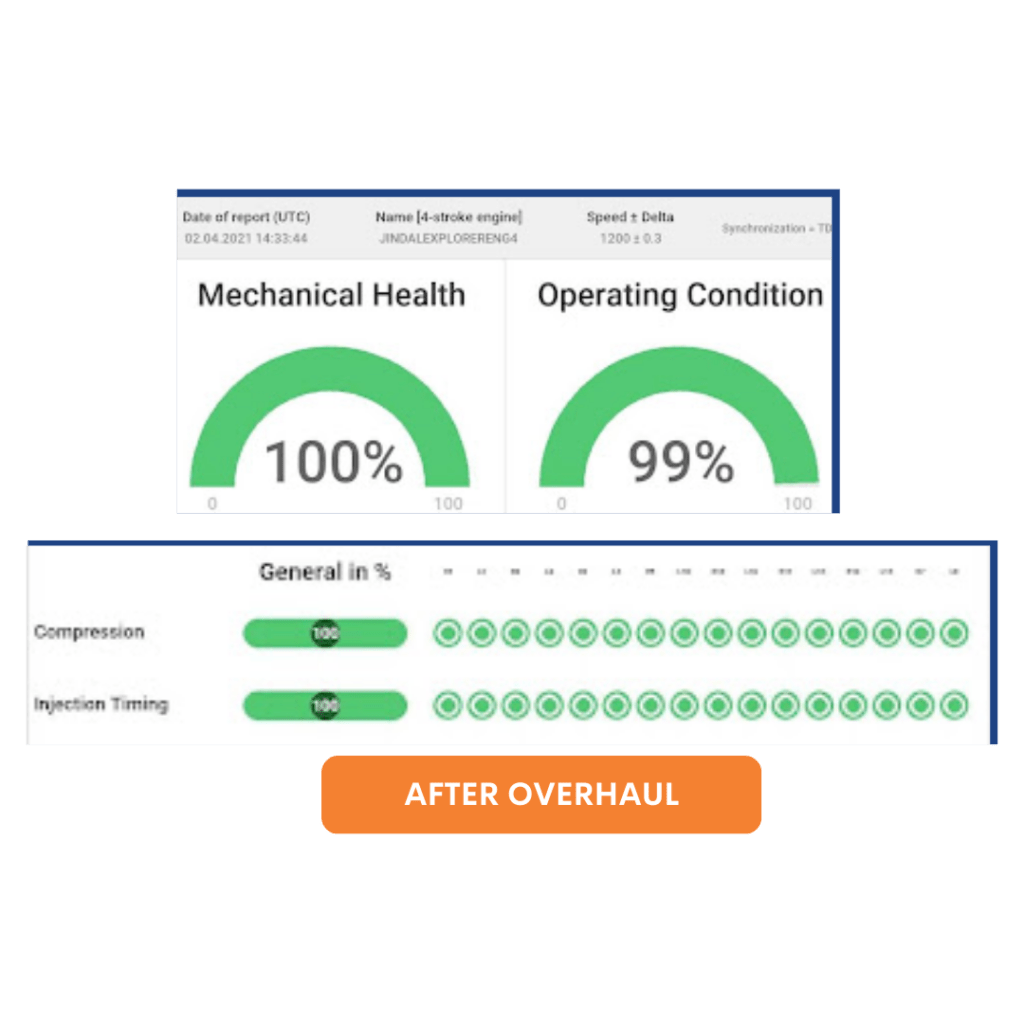

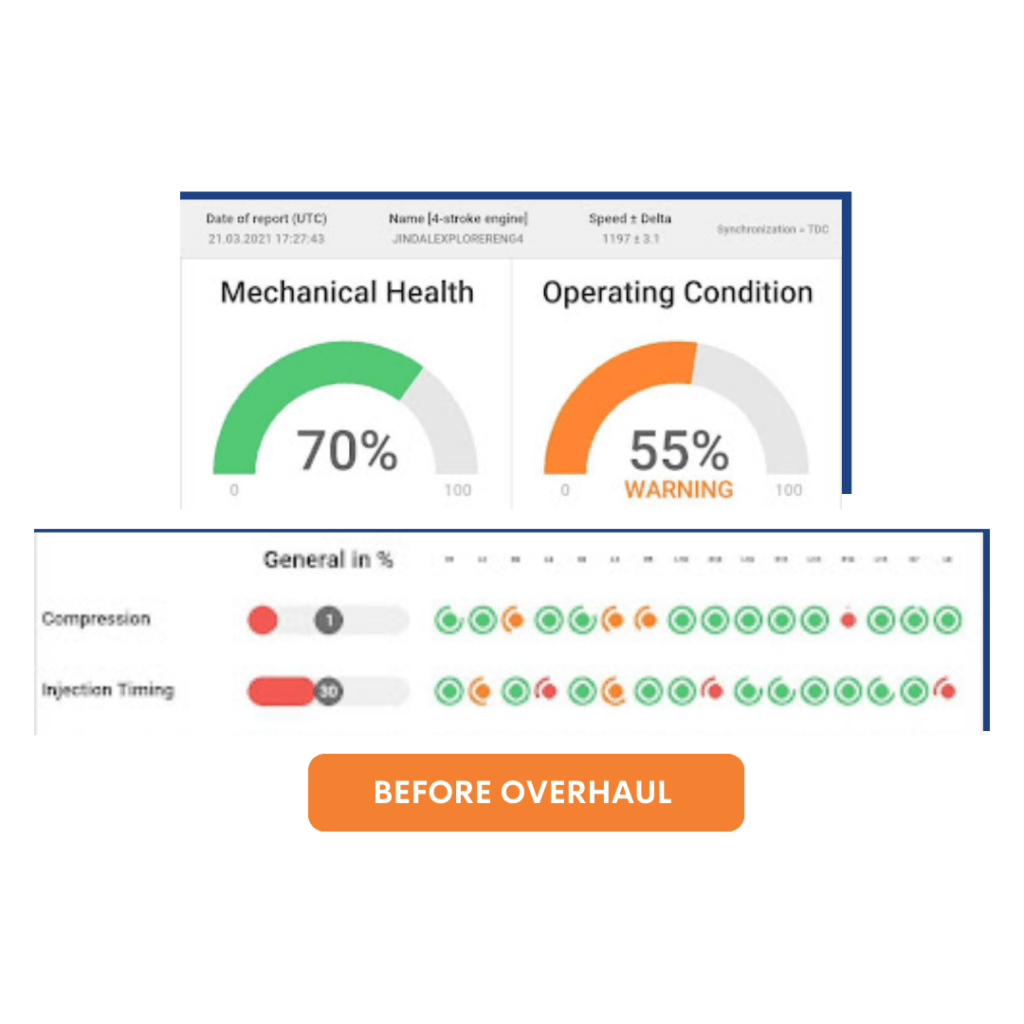

- The Vib360 condition monitoring system was installed on Engine 4 of the vessel to identify problems and monitor the real-time health of the asset.

- MPU sensors were installed on the flywheel to monitor the crank speed signal and TDC signal.

- The system was used to perform an analysis before and after overhaul, at 65% load